-

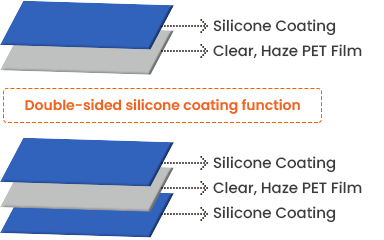

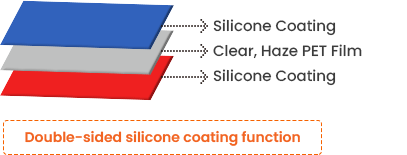

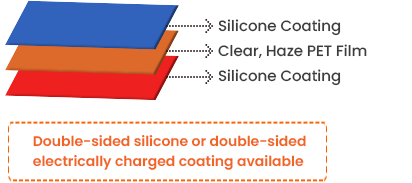

- • PET substrate with excellent heat resistance and tensile performance Silicone mold release treatment on one side and both sides a product that provides uniform and excellent release properties through

- • For precision and industrial products such as medical patches , mobile processes, and protective films realization of excellent applicable physical properties

- • Anti-static function treatment available to improve static electricity problems between processes (105~9)

- • Applicable to optical applications such as OCA

- • Fluorine release treatment possible depending on adhesive characteristics

| PET thickness(um) | Haze(%) | Peel force(g /Inch) | Maximum width(mm) |

|---|---|---|---|

| 19~188 | 1~5 | 3~200 | 1570 |